As industries continue to evolve, the impact of chemical processes on both human health and the environment becomes an increasingly critical concern. With the rise in awareness about sustainability, green chemistry has emerged as a vital field that seeks to develop safer, more sustainable chemical processes. In this blog, we will explore what green chemistry is, how it applies to safety management, and why it is crucial for a safer and more sustainable future.

We will also examine the connection between green chemistry, safety data sheets (SDS), and the role of SDS management software solutions, like those offered by TotalSDS, in supporting green chemistry initiatives.

Common Regulatory and Safety Issues with Chemicals

Chemicals are a fundamental part of many industries, from pharmaceuticals to agriculture and manufacturing. However, they pose various risks that require stringent safety management. One of the most pressing concerns surrounding chemicals is their potential to cause harm to human health and the environment. Regulatory bodies like the U.S. Environmental Protection Agency (EPA) and the Occupational Safety and Health Administration (OSHA) enforce guidelines and regulations to ensure that chemicals are used, stored, and disposed of safely.

Some of the most common safety and regulatory issues associated with chemicals include:

- Toxicity: Many chemicals are harmful to human health, and exposure to them can cause a range of health problems, from respiratory issues to long-term diseases such as cancer.

- Environmental Impact: Certain chemicals, when released into the environment, can contaminate water supplies, soil, and air, leading to long-lasting environmental damage.

- Flammability and Reactivity: Many chemicals are highly flammable or reactive, which can lead to dangerous accidents, including explosions and fires, if not handled properly.

- Waste Disposal: Improper disposal of chemicals can result in contamination of landfills, waterways, and ecosystems, contributing to pollution and hazardous waste accumulation.

Given these challenges, industries need to find ways to mitigate these risks while still meeting their production and operational needs. This is where green chemistry comes into play.

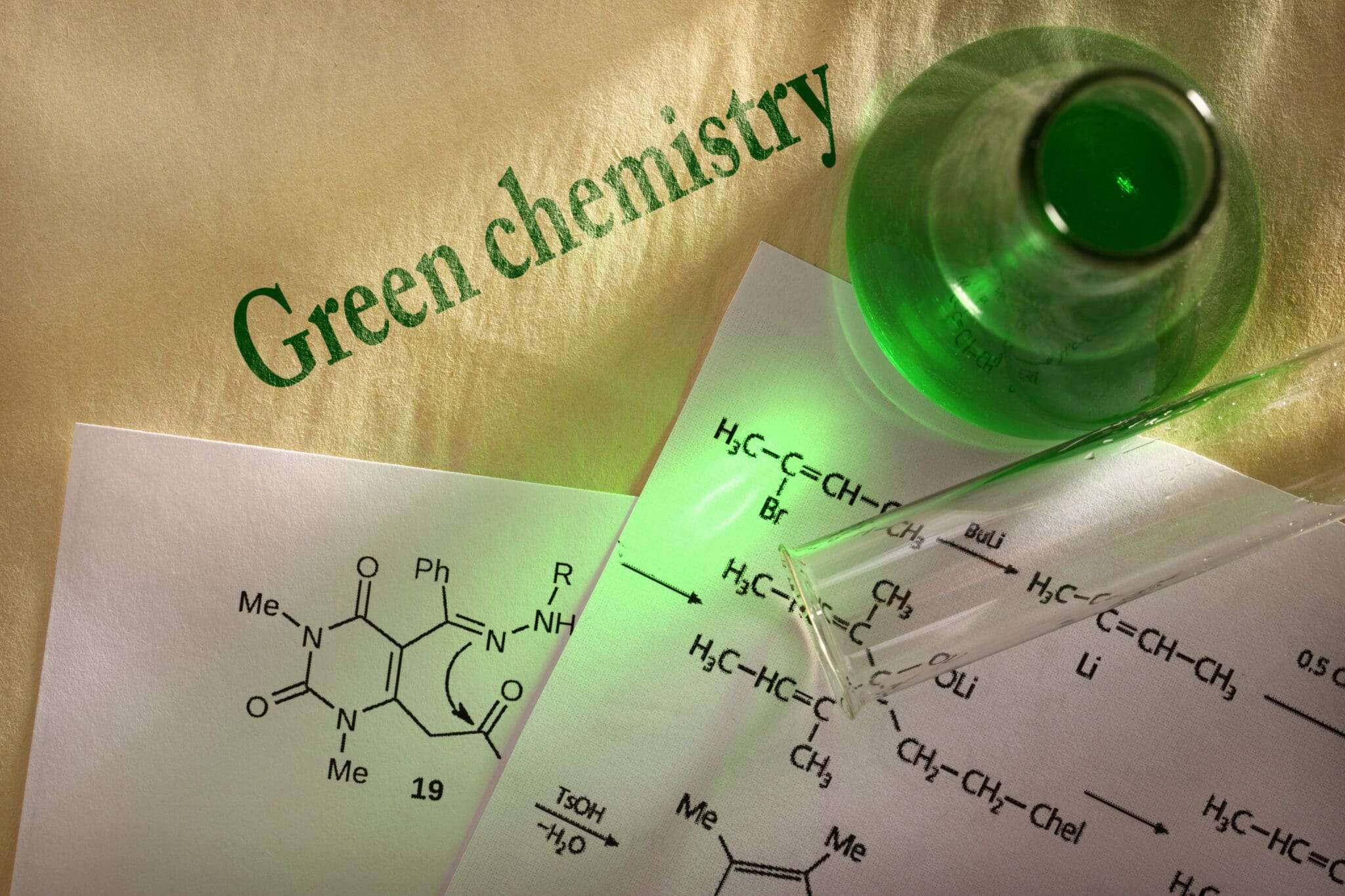

What is Green Chemistry?

Green chemistry, also known as sustainable chemistry, refers to the design and use of chemical products and processes that reduce or eliminate the use and generation of hazardous substances. It aims to make chemical processes more environmentally friendly and safe by focusing on the entire lifecycle of a product — from raw materials to disposal.

The principles of green chemistry were introduced in 1998 by Paul Anastas and John Warner, who developed 12 principles of green chemistry. These principles guide the development of safer chemicals and processes by prioritizing environmental and human health, reducing energy consumption, and minimizing waste.

Some key principles of green chemistry include:

- Prevention: It is better to prevent waste than to treat or clean it up after it’s been created.

- Atom Economy: Chemical reactions should be designed to maximize the incorporation of all starting materials used in the process into the final product.

- Energy Efficiency: Processes should be designed to minimize energy consumption.

- Safer Solvents and Auxiliary Chemicals: Use substances that are less toxic and safer to handle.

- Design for Degradation: Chemicals should be designed so that they break down into non-toxic products after use.

By focusing on these principles, green chemistry promotes innovation that supports environmental sustainability while ensuring the safety of workers and consumers alike.

How Green Chemistry Applies to Safety Management

Green chemistry is deeply tied to safety management because it emphasizes the use of safer chemicals and processes that reduce risks to human health and the environment. By adopting green chemistry practices, companies can improve workplace safety, decrease the likelihood of accidents, and ensure better compliance with safety regulations.

Some examples of how green chemistry applies to safety management include:

- Reducing Hazardous Chemicals: Green chemistry encourages the replacement of toxic or hazardous chemicals with safer, less toxic alternatives. This reduces the risk of exposure and potential harm to employees.

- Minimizing Waste: Green chemistry focuses on reducing waste at the source, thus decreasing the volume of hazardous materials that need to be disposed of and minimizing the risks associated with chemical waste management.

- Energy Efficiency: Many green chemistry techniques are designed to use less energy, which not only reduces costs but also minimizes the environmental footprint of chemical processes.

- Safer Reaction Conditions: Green chemistry encourages the use of milder reaction conditions (e.g., room temperature or neutral pH), which reduces the likelihood of accidents such as fires or explosions.

By integrating green chemistry principles into safety management protocols, companies can better protect their employees, communities, and the environment while still achieving their operational goals.

Why Green Chemistry is Important

Green chemistry is essential for several key reasons, especially as industries strive to balance the need for chemical products with the responsibility to protect human health and the environment. Here are a few reasons why green chemistry is important:

- Environmental Protection: Traditional chemical processes can lead to the generation of harmful waste, emissions, and pollutants. Green chemistry, by contrast, helps minimize the environmental impact of chemical production by using safer materials and more efficient processes. This is vital as global concerns about pollution and climate change continue to grow.

- Public Health: Many chemicals in use today are hazardous to human health. By prioritizing the development of safer chemicals and processes, green chemistry reduces the risks associated with chemical exposure, promoting healthier communities and safer workplaces.

- Economic Benefits: Green chemistry can help companies reduce costs by improving energy efficiency, cutting waste disposal fees, and minimizing the need for hazardous materials handling. Additionally, green products and processes can open up new markets as consumers and businesses increasingly demand environmentally friendly solutions.

- Regulatory Compliance: Many governments around the world are tightening regulations around chemical safety and environmental protection. By adopting green chemistry practices, companies can stay ahead of these regulations and ensure compliance while avoiding fines and reputational damage.

Safety Data Sheets (SDS) and Green Chemistry

Safety data sheets (SDS) are essential documents that provide crucial information about the properties, hazards, and safety precautions for chemicals. They are a vital component of any safety management program, ensuring that employees understand how to handle, store, and dispose of chemicals safely. In the context of green chemistry, SDSs are invaluable tools for identifying safer chemicals, alternative materials, and best practices.

Green chemistry can be integrated into SDSs by including information about the environmental impact, toxicity, and sustainability of chemicals. For instance, SDSs can highlight whether a chemical is a greener alternative to a more toxic substance or if it degrades harmlessly into non-toxic byproducts.

TotalSDS Solutions for Green Chemistry

At TotalSDS, we offer comprehensive SDS management software and authoring tools designed to support green chemistry initiatives. Our SDS management software allows businesses to store, organize, and access up-to-date SDSs in a centralized digital format, ensuring that safety information is easily accessible. Additionally, TotalSDS’s authoring software enables the creation of customized SDSs that can include green chemistry principles, helping companies ensure they are using and promoting safer, more sustainable chemicals.

By leveraging TotalSDS’s software, businesses can streamline their safety management processes while staying aligned with green chemistry principles, ensuring both regulatory compliance and environmental sustainability.