In the fast-paced and inherently hazardous construction and engineering industries, ensuring worker safety is paramount. Among the myriads of safety protocols, the management of Safety Data Sheets (SDS) plays a critical role in hazard communication and overall site safety.

Leveraging digital management software for SDSs not only streamlines compliance but also enhances the protection of workers and the environment.

The Critical Role of Hazard Communication

Hazard communication is a fundamental aspect of workplace safety, especially in industries where workers are routinely exposed to potentially dangerous substances. According to the Occupational Safety and Health Administration (OSHA), hazard communication consistently ranks as the second most cited violation year over year. This statistic underscores the importance of maintaining an effective hazard communication program, which includes an up-to-date and compliant SDS library.

There’s no question that maintaining compliance and safety is crucial for businesses and their employees, however, equally impactful is the potential cost of non-compliance. The new OSHA penalty amounts became effective Jan. 16, 2024, increasing the maximum penalties for serious and other-than-serious violations from $15,625 per violation to $16,131 per violation. In addition, the maximum penalty for willful or repeated violations will increase from $156,259 per violation to $161,323 per violation.

The Link Between Hazard Communication and Safety

Despite falls being the number one citation by OSHA, hazard communication remains a key focus during inspections. When an incident occurs and OSHA conducts an onsite investigation, one of the primary documents they request is the hazard communication program, including the SDSs for any onsite chemicals. This requirement highlights the necessity for companies to have a robust, easily accessible system for managing these documents.

Benefits of Digital SDS Management Software for the Construction Industry

Consider the benefits of digital SDS management software for the construction industry.

-

Enhanced Accessibility and Organization

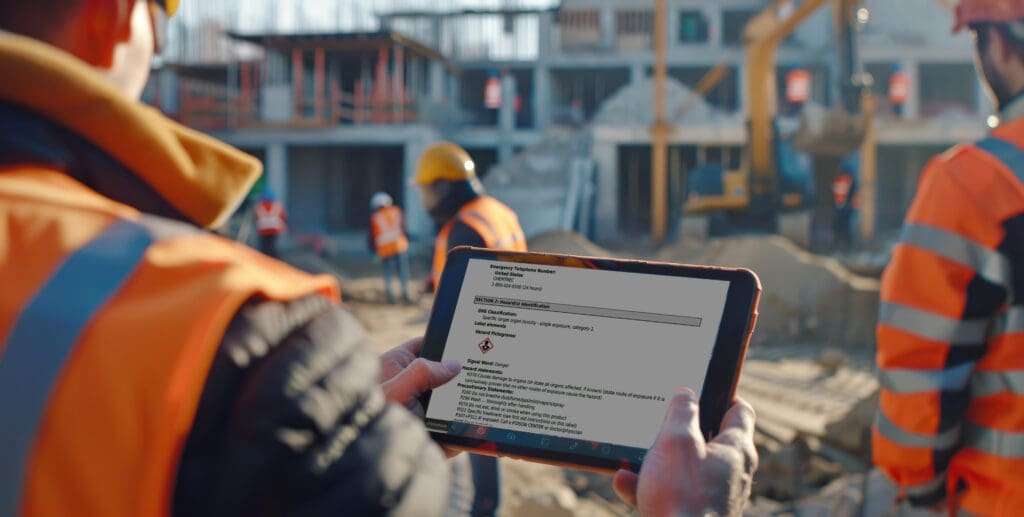

Digital SDS management software allows for the centralized storage and organization of all safety data sheets. Workers and safety managers can quickly access the necessary information from any device, ensuring that critical data is always at their fingertips, even in emergency situations.

-

Improved Compliance and Safety

Maintaining compliance with OSHA regulations can be a daunting task, but digital SDS software simplifies this process. The software facilitates easy document updates which ensures that all SDS documents are current and compliant with regulatory standards. This reduces the risk of citations and enhances overall safety by ensuring that workers have access to the most up-to-date information.

Software that offers a mobile application is an added benefit. When users aren’t required to log in to access information and can simply scan a QR code, the concerns regarding internet access on a construction site become obsolete. With data stored locally on the device, meeting OSHA requirements and ensuring compliance without internet access can be a game-changer.

-

Time and Cost Efficiency

Manual management of SDSs can be time-consuming and prone to errors. Time is spent searching the internet for the correct SDS, printing the SDSs and organizing them into organization within a binder. Digital solutions streamline this process, freeing up valuable time for safety managers to focus on other critical tasks. Additionally, by reducing the risk of non-compliance and potential fines, companies can save significant costs in the long run.

-

Environmental Benefits

Going digital reduces the need for physical paper storage, contributing to a more environmentally friendly workplace. This aligns with the growing emphasis on sustainable practices within the construction and engineering industries.

Real-World Impact: OSHA Regulations on Construction Industry

Safety statistics highlight the tangible benefits of effective hazard communication. According to OSHA, proper hazard communication can prevent numerous accidents and injuries each year. For instance, the Bureau of Labor Statistics reports that in 2022, there were over 200,000 non-fatal injuries in the construction industry alone. Many of these incidents could potentially be mitigated with better hazard communication and SDS management.

Although Fall Protection topped the OSHA violations list by contractors in 2023, with over 5,400 citations, totaling $28.8 million in penalties, Hazard Communication citations made that same top ten list. In 2023, OSHA conducted 252 inspections related to the Hazard Communication standard (1910.1200), which covers the classification and labeling of hazardous materials and mandates companies to inform employees about potential hazards and protective measures. These inspections resulted in $610,522 in penalties.

On average over the past decade, there have been over 38,000 annual OSHA inspections in the construction industry. Implementing and maintaining a compliant hazard communication program is not only a regulatory necessity but also a wise business practice.

In the construction and engineering industries, where the stakes are high, and the environment is dynamic, ensuring that hazard communication is seamless and effective is crucial. Digital SDS management software offers a modern solution that enhances safety, compliance, and efficiency. By investing in these tools, companies can protect their most valuable assets—their workers—while also safeguarding their bottom line and reputation.

Embracing digital transformation in safety management is not just about keeping up with regulations; it’s about leading the way in creating safer, more efficient, and more sustainable workplaces.