For many compliance professionals, OSHA elicits a very negative response. Our hope is that by the end of this article, you’ll have a completely different perspective. The reality is that OSHA’s goal is to make the workplace safer – and that should be your goal, too.

For many compliance professionals, OSHA elicits a very negative response. Our hope is that by the end of this article, you’ll have a completely different perspective. The reality is that OSHA’s goal is to make the workplace safer – and that should be your goal, too.

Because even if you’re not driven by the higher ideals of a safe workplace, the truth is it’s just good business.

It’s been estimated that employee injuries cost U.S. businesses $250 billion every single year in both direct and indirect costs. And unfortunately, if OSHA does end up on your worksite, it can prove expensive. There’s the obvious cost of the citations themselves, the time and hassle of addressing the citations, and other often overlooked costs, such as workers’ compensation, employee morale, replacement of employees, and lost productivity.

There are, however, ways to reduce the impact of an OSHA inspection – and the first step involves knowing more about them.

TRUE or FALSE: You should comply with OSHA regulations because it’s inevitable that, sooner or later, you will be inspected.

This is surprisingly false.

Just as most of us don’t wear a seatbelt simply because it’s the law but rather because it can save our lives, the real reason you should comply with OSHA regulations is it’s simply smart to be safe.

It Won’t Happen To Me – Or Will It?

Statistically speaking, the numbers say it won’t happen to you.

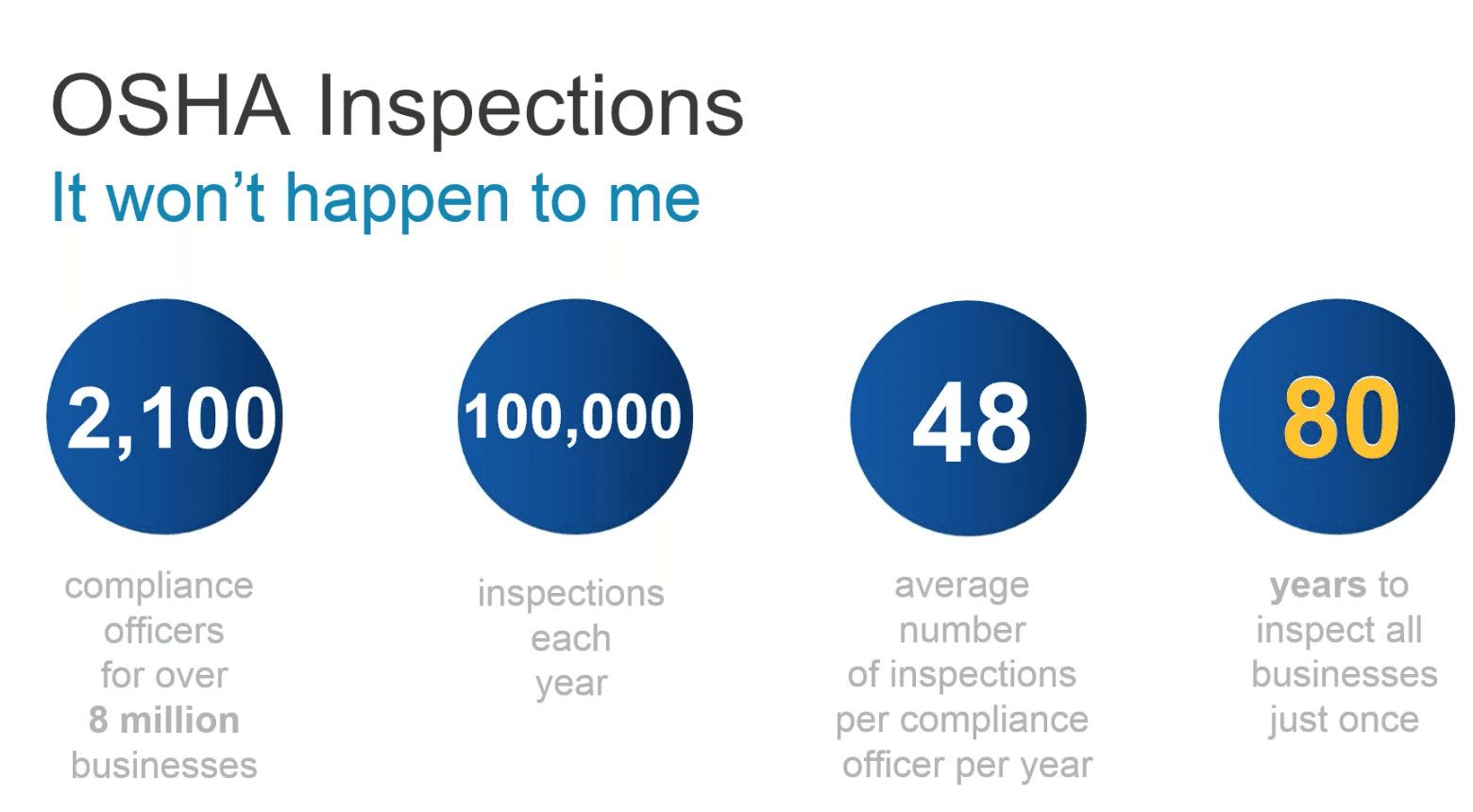

With roughly 2,100 compliance officers for over 8 million businesses, that’s almost 4,000 businesses per compliance officer. And while OSHA does inspect 100,000 worksites each year, if you do the math, that means, on average, each compliance officer does about 48 inspections per year.

At that rate, do you know how many years it would take OSHA to inspect all the businesses in the U.S. just once? Eighty years.

Low-Hanging Fruit

Most people think that OSHA targets certain industries and that this accounts for most of the inspections. While there is some truth to this, it’s not the full picture. OSHA has two types of inspections: programmed and unprogrammed. OSHA does – understandably – target certain industries and companies based on where they believe the greatest risks are, so those inspections are programmed.

However, 86 percent of inspections are unprogrammed, resulting from injuries, fatalities, complaints, and referrals. And 46 percent of unprogrammed inspections are the result of complaints by employees. Your employees can file an anonymous complaint with OSHA because they know if you’re looking out for their safety – and they also often know if you’re not in compliance with regulations.

And employee complaints are OSHA’s highest priority, second only to situations involving imminent danger or severe injuries and illnesses. That means that over one-third of all inspections are due to employee complaints.

Ways To Increase Or Decrease Your Risk

When you run the numbers, there’s roughly a 1 percent chance of an OSHA inspection. But because so many inspections are due to employee complaints, there are things you can do to both positively – and negatively – affect the likelihood that you’ll be inspected by OSHA.

If your goal is a safer workplace, then not only will you save money on all costs mentioned earlier, but you can decrease the chances you’ll trigger an OSHA inspection. Further, employees who feel safe at work and believe you care about their safety they are less likely to file a complaint.

Does that mean that there aren’t disgruntled employees that can still file a complaint? Of course not. But if OSHA does end up on your doorstep, it will quickly become apparent that you really are trying to make the workplace safer and that, in and of itself, will go a long way.

Some Frequently Asked Questions About Inspections

- Are inspections usually scheduled? No, but also not all interactions with OSHA involve in-person visits.

- Can you refuse a compliance officer access to your workplace? While you do have the right to ask the OSHA compliance officer to obtain an inspection warrant before entering the workplace, it’s best that you speak with an OSHA attorney for legal advice.

- Why is hazard communication cited so often? For years, HazCom has been in the top-three OSHA citations – and for several reasons. First, employee safety begins and ends with adequately communicating the hazards to which employees are exposed. Another reason it’s so often cited is that if you read the OSHA field manual, part of their standard procedure is to look at your hazard communication program, your safety data sheets, and your chemical hazard list – regardless of the reason, they are there. So unlike any other regulation, the hazard communication standard applies to virtually every inspection.

While the odds of a spontaneous inspection are incredibly slim, there are ways to trigger an OSHA inspection – and certainly ways to prevent it, too. So if you’re looking for a partner to help to stave off an inspection while also making sure you’re always compliant should you ever trigger one, get in touch with the compliance experts at GSM today.

To learn more about this topic, check out GSM’s Safety in 10 (minute) webinar series.